When it comes to choosing the right implant solution in CMF surgery, you have a huge range of different shapes, sizes, thicknesses and even materials at your disposal. Apart from standard materials like titanium, sometimes resorbable implants can be a beneficial option. In this interview Jana from our Product Management Implant Systems points out what you can do with our resorbable implants, how they work and also how it all started with a Swiss wood-processing technology company.

What are resorbable implants?

Resorbable implants opposed to e.g. titanium implants dissolve in the patient’s body over time. You can use these kind of implants to treat fractures in minor load-bearing areas such as the midface– so the fracture is stable and the implant holds the two fracture parts in place. After some weeks or months when the fracture has already started to consolidate, the resorbable implant starts to dissolve. A big advantage coming with this is that you do not need a second operation to remove the foreign body.

Titanium osteosynthesis vs. resorbable osteosynthesis with SonicWeld Rx®

When we started working with our resorbable materials Resorb x our ultrasonic bone-welding device SonicWeld Rx® was not yet invented. Therefore, the principle was the same as with the titanium osteosynthesis – screws and plates. The problem was that the screws broke and/or had not enough stability to hold fractures in place.

As alternative you could use titanium screws and plates. With titanium we had enough stability. However, in children who grow quickly, we would see migrating implants – titanium implants would grow into the bone. In the cranium area this is especially dangerous and can harm the brain.

So, for treating young patients, the surgeon had two possibilities which both were not ideal.

1. First, titanium screws with high stability, but which could grow through the bone (especially in young patients) and therefore could be dangerous. They also had to be removed in a second operation.

2. Second, we could use the resorbable plates and screws that did not have to be removed, but their mechanical strength was less predictable which was why there was no guarantee to hold fractures securely in place.

Therefore, we steadily searched for new and different opportunities - and found it with the SonicWeld Rx® system.

How it all started

It all started when Karl Leibinger himself found out about the company WoodWelding® from Switzerland who found a way to insert polymer dowels into wood using ultrasound to create a welding effect. . Being fascinated by the easy and fast way of inserting these dowels into wood and the analogy of wood and bone, our engineers were thinking of the challenge of applying resorbable materials in CMF surgery.

As wood has a similar cavity structure as human bones we further developed the technique and finally created a device that can weld resorbable material into the bone. Long story short: SonicWeld Rx® was born! Clearly, this was a „revolution“ at that time. Therefore, there are dozens of publications about this topic, which confirm the functionality of the system.

How does the device work?

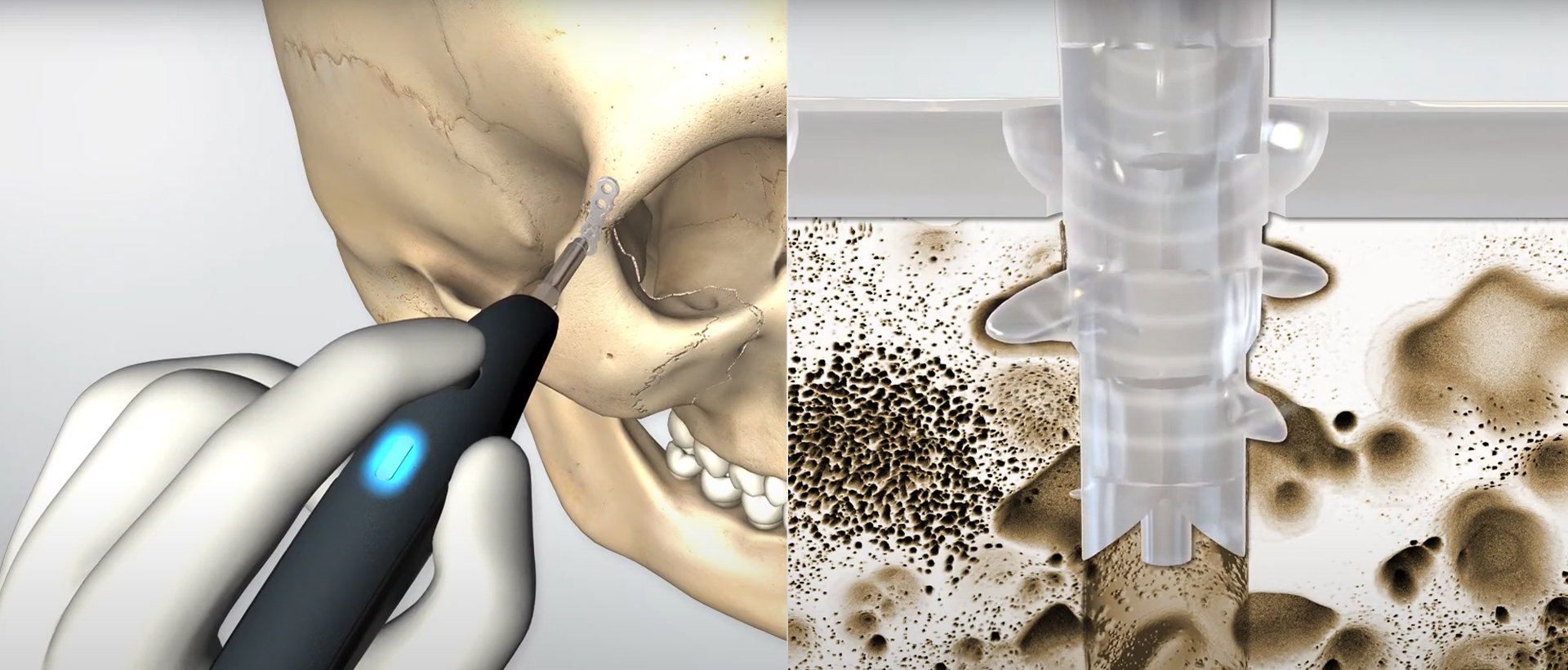

For working with the SonicWeld Rx® device resorbable plates e.g. Resorb x and (way more important) resorbable Sonic Pins Rx® are needed. The plates have to be preheated in the Xcelsior water bath and placed over the fracture in order to shape it. Then a hole for a SonicPin Rx® is predrilled. Afterwards, the pin is placed above it. When activated the sonotrode ultrasonic energy concentrates through the tip of the sonotrode. The ultrasonic energy leads to a vibration of the SonicPin Rx®. The pin changes its state of aggregation and starts flowing into the bone cavities (the so-called cancellous bone). The resorbable material immediately solidifies again and the pin is securely placed in the bone. All this happens in seconds as the video shows.

Another significant benefit is that the “melting” of the pin head allows it to become one with the plate after it solidifies again. This creates an even higher stability.

When is SonicWeld Rx® used?

SonicWeld Rx® is most often used in young children mainly aged 0,5 – 5 years with a cranial deformity. In children without such a cranial defect the cranium sutures are still open to give the brain enough space to grow and after some years these sutures grow together. In children with so-called craniosynostosis the sutures of the cranium are already prematurely fused. When this is the case the head shape looks slightly deformed.

Other indications are fractures in the midface. In the facial area the surgeons also want to make sure that they have as small and as little scars as possible. With resorbable materials we do not need a second surgery in this aesthetically crucial region. Additionally, we have an implant that does not stay in the body or that is palpable and can irritate the soft tissue.

For dental applications, we also offer several solutions which help with the augmentation of the alveolar ridge. This means mostly that we prepare a patient’s jaw for the placement of dental implants.

Important to mention here is that the SonicWeld Rx® and the resorbable materials should not be used in load-bearing areas such as the mandible! In this area a stable hold of our resorbable plates cannot be guaranteed, because the forces are too strong.

We have two resorbable materials in our portfolio: Resorb x and Resorb xG. What is the difference?

The main difference is the composition of them both. Which one to choose eventually depends on the surgeon’s preference.

1. On the one hand, we have the Resorb x material which is 100% PDLLA. Resorb x is our traditional material and in Europe still our best sold and most popular one.

2. On the other hand, we have the Resorb xG, which we added to our portfolio in 2013. This consists of 85% PLLA and 15% PGA. It is meanwhile our top-seller in North America.

And of course we want to keep on adding materials and new products to our portfolio ;) So... stay tuned!